QuickCAM – Advanced Machining

World Class CNC software for advanced machining and automation

- NEW state-of-the-art CNC software platform

- New platforms enable new features and developments, never before seen!

- New developments in collaboration with industry leaders

- 30% increase in output from the same machines

- New ground breaking developments to drive increased output

QuickCAM’s CNC software for machining and production control has been completely redeveloped in recent years using modern software platforms and contains new features developed in collaboration with some of the most advanced and knowledgeable flat panel manufacturers in our industry.

By working closely with the industry we have carefully identified modern manufacturing needs and created fresh solutions .

The result is a truly exceptional program, which has a myriad of newly developed features never before seen in manufacturing for this industry.

QuickCAM Production provides time saving methods, which can save hours in the production office and again at the machine.

It will improve the flow of data and information throughout the manufacturing environment and save you money every step of the way.

Consider for a moment how all your software options claim to be able to do everything. This is probably true, designing, customising, costing, quoting, nesting, etc. However, the real question is how well they can perform those features and how effective they are in your business.

If you are not absolutely certain about this, ask QuickCAM Systems to provide you with “proof of concept”¯ to use as a comparison with our competitors. Be sure you are making the right decision.

Some of the outstanding features of QuickCAM Production are:

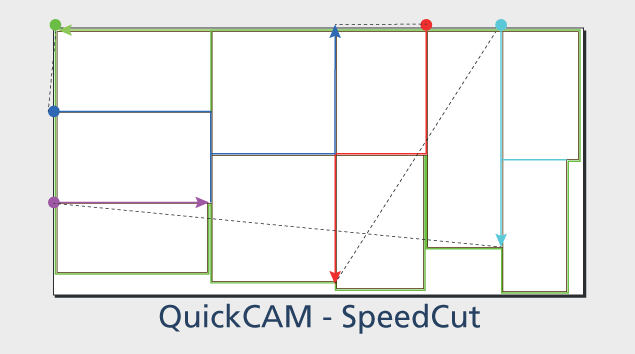

- SpeedCut – The newest addition to our range of optimisation options can increase the throughput on any machine by 15% to 30% while also providing savings on tooling, maintenance and general wear and tear on the machine.

Read more about SpeedCut – Advance Nested Cutting.

- Choose to run to one or many machines at the same time

- Production runs can be batched, sent to multiple lines and are ready to run everywhere. If you need to change machines there is no need to re-run the whole job.